Mash is a form of a complete feed that is finely ground and mixed so that birds & Cattle cannot easily separate out ingredients & each mouthful provides a well-balanced diet. Mash Feed is the simplest solid feed form that can be manufactured. It consists of grinding and mixing of all raw materials into the correct proportions to meet nutritional requirements of the birds & Cattle. No additional heat- or compaction treatments are conducted on the feed; hence, energy expenditure to prepare the feed is low compared to pellets and extruded feed.

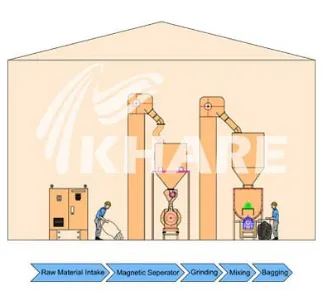

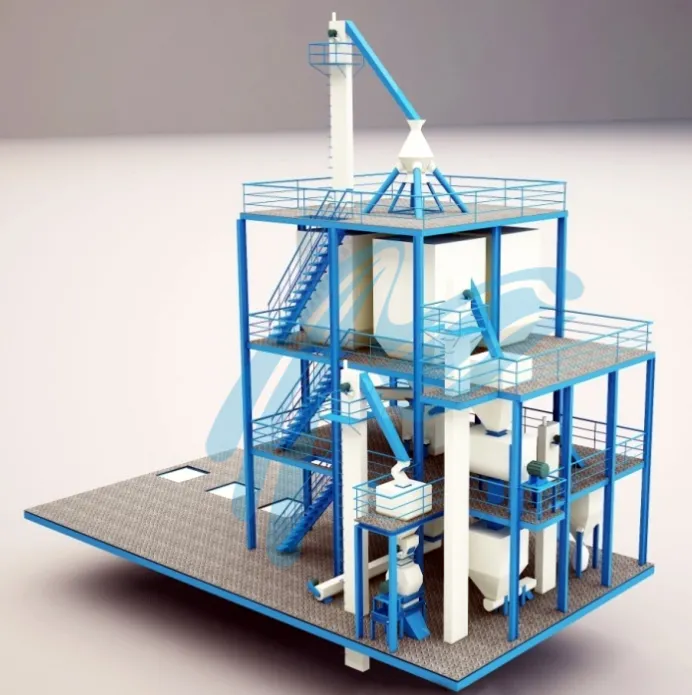

Mash Feed Plant

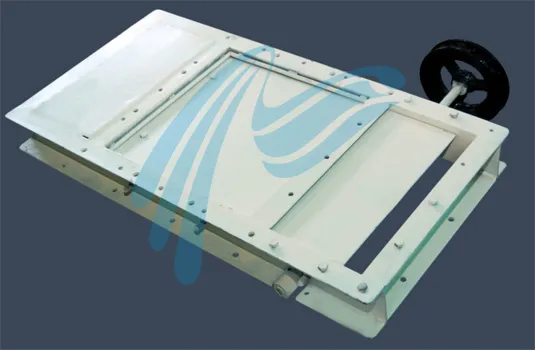

Mash Feed Plant is designed to process the feed in mash form to make them suitable for animals & Birds. This plant contains hammer mill or grinders to grind the ingredients and convert it in the powder form in right proportions for availing homogenous feed. It comes with a reliable magnetic separator or Cascade magnet to separate ferrous material like iron particles etc, from the raw material. The Plant is designed such that it emit minimum dust, vibration and noise.

Features of Mash Feed Plant

The Plant Consists of Following Key Components

Salient Features

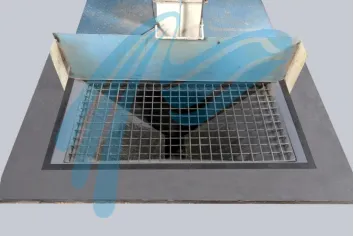

After all ingredients weighing and batch formulation as per requirement the batch is poured manually into the intake dump hopper of feeding bucket elevator.

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Salient Features

Models

Features

| Model | Power Requirement | Capacity per 8 hr. Shift | |

| Grinder | Mixer | ||

| Grindmix V 150 | 3 H.P. | 1 H.P. | 4 to 4.5 tons (150 kg.batch) |

| Grindmix V 300 | 5 H.P. | 2 H.P. | 6 to 7 tons (300 kg.batch) |

Features

H-Series is a batch type machine in which grinding & mixing is performed simultaneously.

Features

H-Series is a batch type machine in which grinding & mixing is performed simultaneously.

Features

H-Series is a batch type machine in which grinding & mixing is performed simultaneously.

Features

H-Series is a batch type machine in which grinding & mixing is performed simultaneously.

Features

H-Series is a batch type machine in which grinding & mixing is performed simultaneously.

Features

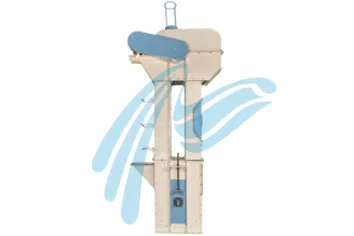

This plant is equipped with a bucket elevator, cascade magnet,rotary vane feeder,full screen hammer mill,storage hopper, mixer with different configuration for different capacities.

Features

This plant is equipped with a bucket elevator, cascade magnet,rotary vane feeder, full screen hammer mill, storage hopper, mixer with different configuration for different capacities.

Features

In A feed Processing, Mixing of raw materials is according to the feed formula with precise proportion. Batching the raw material manually is not so accurate, which results in the inferior quality of feed. But by adapting an Auto batching system can solve the problem of material quality and can also help in higher productivity of the feed manufactured. Adapting this system can also reduce labour cost.thus auto batching system is provided .